Our Services

Spray Foam Insulation

Spray Foam Insulation is a cutting-edge insulation solution that offers unparalleled thermal performance and air sealing in a single application. This innovative material is applied as a liquid that quickly expands up to 30-60 times its original volume, filling every nook, cranny, and void to create a seamless barrier against heat transfer and air infiltration.

There are two main types of spray foam insulation: open-cell and closed-cell. Open-cell foam is softer, more flexible, and slightly permeable, making it ideal for interior walls and soundproofing applications. Closed-cell foam, on the other hand, is denser, more rigid, and offers a higher R-value per inch, making it an excellent choice for areas where maximum insulation is needed, such as attics, basements, and exterior walls.

Benefits of Spray Foam Insulation: Energy Efficiency:

By eliminating air leaks and providing a high R-value, spray foam significantly reduces energy loss, leading to lower heating and cooling costs. It can save homeowners up to 50% on energy bills compared to traditional insulation methods.

Moisture Barrier:

Unlike other insulation materials, closed-cell spray foam also acts as a moisture barrier, preventing water infiltration that can lead to mold growth, wood rot, and structural damage.

Air Sealing:

Spray foam creates an airtight seal that blocks outside air from entering and conditioned air from escaping, enhancing comfort and indoor air quality by reducing drafts and allergens.

Soundproofing:

Open-cell spray foam is excellent at absorbing sound, making it ideal for reducing noise transmission between rooms or from the outside.

Longevity and Durability:

Spray foam insulation does not sag, settle, or degrade over time, ensuring long-term performance and reliability. It also adds structural strength to walls and roofs due to its rigid nature.

Environmental Impact:

Many spray foam products are made with environmentally friendly materials, including those with low global warming potential (GWP) blowing agents, contributing to a more sustainable home. Spray Foam Insulation is a versatile solution suitable for new construction, retrofits, and hard-to-insulate areas.

Whether you’re looking to improve your home’s energy efficiency, increase comfort, or add value to your property, spray foam insulation is an investment that pays off in the long run.

Blown-In Insulation

Blown-In Insulation is a highly effective and versatile insulation method, ideal for filling irregularly shaped spaces and hard-to-reach areas such as attics, walls, and floors. This insulation type consists of small particles, typically made from materials like fiberglass, cellulose, or mineral wool, that are blown into place using specialized equipment. The process creates a dense, seamless blanket of insulation that conforms to any space, ensuring comprehensive coverage.

Types of Blown-In Insulation:

Fiberglass Blown-In Insulation:

Made from fine glass fibers, this type is lightweight and provides excellent thermal resistance. It’s commonly used in attics and walls to improve energy efficiency and maintain consistent indoor temperatures.

Cellulose Blown-In Insulation:

Composed primarily of recycled paper products treated with fire retardants, cellulose insulation is an environmentally friendly option that offers superior coverage and soundproofing. Its dense composition makes it particularly effective in reducing air infiltration and improving energy efficiency.

Mineral Wool Blown-In Insulation:

Derived from natural rock or industrial by-products, mineral wool is naturally fire-resistant and provides excellent thermal and acoustic insulation. It’s particularly suitable for areas where fire safety is a priority.

Benefits of Blown-In Insulation:

Comprehensive Coverage:

Blown-in insulation is perfect for filling gaps, cracks, and voids in attics, walls, and floors, where traditional batt insulation might leave spaces exposed. Its ability to conform to any shape ensures maximum coverage and energy efficiency.

Energy Efficiency:

By reducing heat loss in the winter and heat gain in the summer, blown-in insulation helps maintain a consistent temperature throughout your home. This can lead to significant savings on heating and cooling costs.

Soundproofing:

The dense application of blown-in insulation materials effectively dampens sound, making it an excellent choice for reducing noise transmission between rooms or from outside sources.

Quick Installation:

The installation process for blown-in insulation is relatively quick and minimally invasive. Professional installers can efficiently insulate large areas without the need for extensive construction or renovation work.

Eco-Friendly Options:

With materials like cellulose made from recycled paper products, blown-in insulation can be a sustainable choice for homeowners looking to reduce their environmental impact.

Fire Resistance:

Certain types of blown-in insulation, such as mineral wool, offer inherent fire resistance, adding an extra layer of protection to your home.

Improved Air Quality:

Blown-in insulation helps to seal out dust, allergens, and outdoor pollutants, contributing to better indoor air quality and a healthier living environment.

Applications of Blown-In Insulation:

Attics: Blown-in insulation is particularly effective in attics, where it can be blown over existing insulation to increase R-value and improve energy efficiency.

Walls: It can be installed in both new construction and existing walls, filling cavities and improving thermal performance.

Floors: Blown-in insulation can be used in floors, particularly in basements and crawl spaces, to enhance comfort and reduce energy loss.

Blown-In Insulation is a cost-effective, high-performance option that offers excellent coverage and energy savings for homeowners. Whether you’re upgrading existing insulation or insulating a new space, blown-in insulation provides a reliable solution that enhances comfort, reduces energy costs, and contributes to a more sustainable home.

Whole House Air Sealing

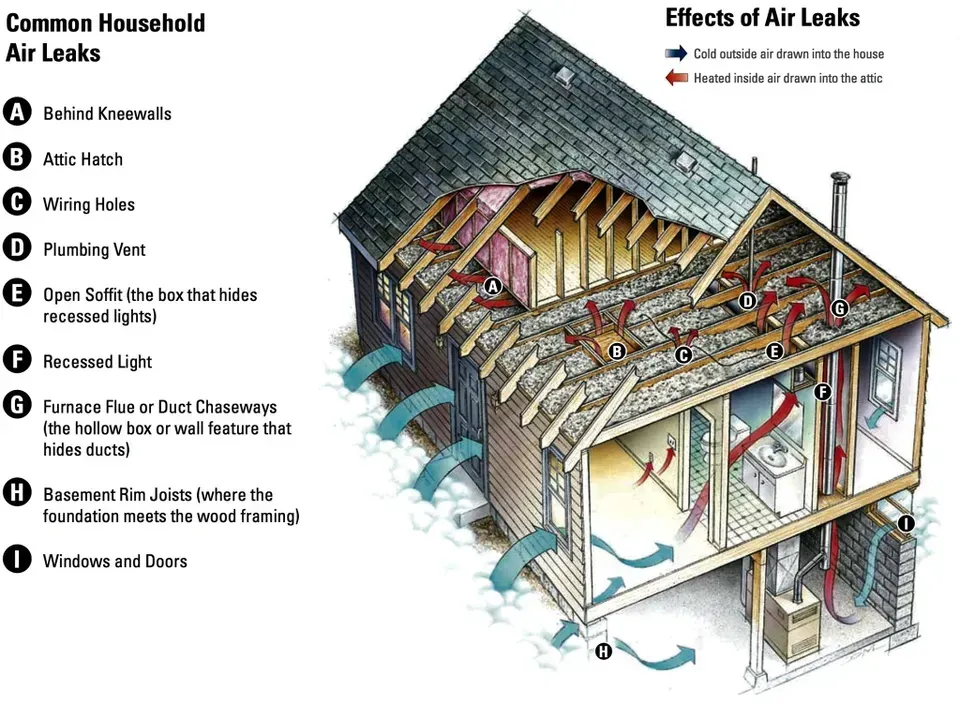

Whole House Air Sealing is a comprehensive process designed to identify and seal hidden air leaks throughout your home, ensuring maximum energy efficiency, comfort, and indoor air quality. Air leaks occur in various parts of a home, including around windows and doors, in the attic, basement, and through gaps in walls, floors, and ceilings. These leaks allow conditioned air to escape and unconditioned air to enter, leading to increased energy consumption, higher utility bills, and reduced comfort.

Key Areas Addressed in Whole House Air Sealing:

Attic:

The attic is one of the most common areas for air leaks due to gaps around vents, chimneys, and insulation. Sealing these leaks prevents warm air from escaping in the winter and keeps hot air out in the summer, reducing the load on your HVAC system.

Windows and Doors:

Gaps around windows and doors are notorious for letting drafts in. Weatherstripping, caulking, and other sealing methods are used to eliminate these leaks, improving comfort and energy efficiency.

Basement:

Basements often have air leaks around pipes, ducts, and foundation walls. Sealing these areas not only improves energy efficiency but also helps to prevent moisture intrusion and pest problems.

Walls, Floors, and Ceilings:

Hidden leaks in walls, floors, and ceilings, especially where different building materials meet, can be sealed with specialized materials to create a continuous barrier against air infiltration.

Ductwork:

Leaky ducts can account for significant energy losses. Sealing and insulating ducts ensures that the air your HVAC system works hard to heat or cool is delivered efficiently to every room.

Benefits of Whole House Air Sealing:

Energy Savings:

By eliminating air leaks, your heating and cooling systems operate more efficiently, leading to substantial energy savings. Sealing can reduce your energy bills by up to 20% or more, depending on the extent of the leaks.

Improved Comfort:

Air sealing helps maintain a consistent temperature throughout your home, eliminating cold drafts in the winter and reducing hot spots in the summer. This creates a more comfortable living environment year-round.

Enhanced Indoor Air Quality:

Sealing air leaks reduces the infiltration of outdoor pollutants, allergens, and moisture, contributing to better indoor air quality. This is particularly important for homes in areas with high pollen counts or pollution.

Increased Durability:

Air sealing helps protect your home’s structure by minimizing moisture buildup that can lead to mold growth, wood rot, and other issues. This can extend the life of your home’s building materials and reduce maintenance costs.

Environmental Impact:

By reducing energy consumption, whole house air sealing also reduces your home’s carbon footprint, making it an environmentally responsible choice for energy-conscious homeowners.

Pest Prevention:

Sealing gaps and cracks also helps to keep out pests like insects and rodents, which can enter your home through small openings.

The Air Sealing Process:

Assessment: The process begins with a thorough energy audit, where professionals use tools like blower doors and infrared cameras to locate air leaks throughout your home.

Sealing: Once leaks are identified, they are sealed using a variety of materials, including caulk, spray foam, weatherstripping, and specialized tapes.

Verification: After sealing, a final assessment is often conducted to ensure that the air leaks have been effectively eliminated and that your home is now more energy-efficient.

Whole House Air Sealing is a smart investment for homeowners looking to improve their home’s energy efficiency, comfort, and indoor air quality. By addressing air leaks throughout your home, you’ll enjoy lower energy bills, a more comfortable living environment, and the peace of mind that comes with a well-sealed, energy-efficient home.

Sound Proofing

Sound Proofing is a specialized service designed to reduce noise transmission between rooms or from outside sources, creating a quieter, more peaceful environment in your home or business. Whether you’re looking to enhance privacy, improve the acoustics of a room, or simply block out unwanted noise, sound proofing solutions can be tailored to meet your specific needs.

Key Areas and Techniques in Sound Proofing:

Walls: Soundproofing walls involves adding materials that absorb or block sound waves. This can include the installation of soundproof insulation, such as mineral wool or acoustic foam, within wall cavities, as well as the use of soundproof drywall, which is denser and more effective at blocking sound.

Floors and Ceilings: Noise from footsteps, conversations, and other activities can easily travel through floors and ceilings. Soundproofing these areas may involve adding insulation between floor joists, installing acoustic underlayment beneath flooring materials, or adding resilient channels to ceilings to decouple them from the floor above, reducing sound transmission.

Doors and Windows: Gaps around doors and windows are common sources of noise infiltration. Soundproofing these areas typically includes the use of weatherstripping, acoustic seals, and soundproof curtains or panels. In some cases, upgrading to soundproof doors and windows may be recommended for optimal noise reduction.

Ductwork and Vents: Sound can travel through ductwork and vents, carrying noise from one room to another. Soundproofing solutions for ductwork include adding acoustic linings or installing sound attenuators to reduce noise transmission.

Specialized Acoustic Panels: For rooms requiring high levels of sound control, such as home theaters, recording studios, or conference rooms, the installation of acoustic panels can effectively absorb sound and improve room acoustics. These panels can be customized in terms of size, shape, and design to blend seamlessly with the room’s decor.

Benefits of Sound Proofing:

Enhanced Privacy: Soundproofing helps prevent conversations and noises from being overheard between rooms or from outside, providing greater privacy for you and your family or colleagues.

Improved Comfort: By reducing noise levels, soundproofing creates a more peaceful and comfortable environment, making it easier to relax, concentrate, or sleep.

Better Acoustics: In spaces like home theaters, music rooms, or offices, soundproofing not only blocks unwanted noise but also enhances the acoustics of the room, providing clearer, more balanced sound.

Increased Property Value: Soundproofing is an attractive feature for potential buyers or tenants, especially in urban areas or multi-family dwellings, where noise can be a significant concern.

Reduced Noise Pollution: By preventing noise from escaping or entering your space, soundproofing contributes to a quieter neighborhood and reduces your impact on those living or working nearby.

Health Benefits: Excessive noise can contribute to stress, sleep disturbances, and other health issues. Soundproofing helps mitigate these risks by creating a quieter, more serene living or working environment.

Sound Proofing is a valuable investment for anyone looking to improve the quality of their living or working environment. Whether you’re dealing with noisy neighbors, busy streets, or simply want to create a space where you can enjoy peace and quiet, professional soundproofing solutions offer the perfect balance of functionality and comfort.

Fire Proof Coating

Fire Proof Coating is a specialized protective layer applied to building materials and structures to significantly enhance their resistance to fire and high temperatures. This coating serves as a critical line of defense in preventing the spread of flames, reducing the impact of fire, and protecting the structural integrity of your home or business in the event of a fire.

How Fire Proof Coating Works:

Fire proof coatings are typically composed of intumescent or fire-retardant materials that react when exposed to high temperatures.

Intumescent Coatings: These coatings expand and form a thick, insulating char layer when exposed to heat. This char layer acts as a barrier, slowing down the transfer of heat to the underlying material and providing crucial time for evacuation and fire-fighting efforts. Intumescent coatings are often used on structural steel, wood, and other materials that need protection from high temperatures.

Fire-Retardant Coatings: These coatings are designed to chemically interfere with the combustion process, either by releasing gases that inhibit flames or by forming a protective barrier over the material. Fire-retardant coatings are commonly used on surfaces like walls, ceilings, doors, and furniture to prevent them from catching fire or to slow the spread of flames.

Benefits of Fire Proof Coating:

Enhanced Fire Resistance: Fire proof coatings significantly increase the fire resistance of materials, providing critical protection for your property and giving occupants more time to evacuate safely in the event of a fire.

Structural Integrity: By slowing the spread of fire and reducing heat transfer, fire proof coatings help maintain the structural integrity of your building, preventing collapse and minimizing damage.

Compliance with Building Codes: Many building codes and safety regulations require the use of fire-resistant materials and coatings in certain structures. Applying fire proof coatings ensures compliance with these standards, helping you avoid penalties and ensuring the safety of your building.

Versatility: Fire proof coatings can be applied to a wide range of materials, including wood, steel, concrete, and fabric, making them suitable for various applications in residential, commercial, and industrial settings.

Aesthetic Flexibility: Modern fire proof coatings are available in various finishes, including clear, tinted, or colored options, allowing you to maintain the aesthetic appeal of your building while ensuring safety.

Long-Term Protection: Fire proof coatings are designed for durability, providing long-lasting protection against fire and heat with minimal maintenance. They are resistant to weathering, moisture, and UV radiation, ensuring that the protective layer remains effective over time.

Applications of Fire Proof Coating:

Structural Steel: Applying fire proof coating to steel beams and columns helps prevent the structural collapse of buildings during a fire by delaying the temperature rise in the steel.

Wooden Structures: Fire proof coatings on wood surfaces reduce the risk of ignition and slow the spread of fire, making them ideal for homes, commercial buildings, and historic structures.

Interior Surfaces: Walls, ceilings, and doors in high-risk areas, such as kitchens, electrical rooms, and exits, can be coated to enhance fire safety.

Textiles and Fabrics: Curtains, drapes, and upholstery can be treated with fire-retardant coatings to reduce the risk of fire in residential and commercial spaces.

Concrete: Concrete structures can benefit from fire proof coatings that prevent spalling (the breaking or flaking of concrete when exposed to high temperatures) and maintain the material’s integrity during a fire.

Fire Proof Coating Process:

Assessment: The process begins with an evaluation of your property’s fire risk areas and the materials that require protection.

Preparation: Surfaces to be coated are cleaned and prepared to ensure proper adhesion and effectiveness of the fire proof coating.

Application: The fire proof coating is applied using specialized equipment, such as spray guns or brushes, depending on the material and area being treated.

Curing: After application, the coating is allowed to cure, forming a durable and protective layer that will activate in the presence of fire or high temperatures.

Inspection: Once the coating is cured, an inspection is conducted to verify that the coating has been applied correctly and meets the required fire resistance standards.

Fire Proof Coating is a crucial investment in the safety and longevity of your property. By enhancing the fire resistance of key building materials, you not only protect your investment but also ensure the safety of occupants and help prevent catastrophic losses in the event of a fire.

Why is it Important to Address Air Leaks?

Energy Efficiency:

Sealing air leaks reduces the amount of energy needed to heat or cool your home, leading to lower utility bills and a reduced carbon footprint.

Comfort:

By eliminating drafts, you can maintain a more consistent and comfortable temperature throughout your home.

Indoor Air Quality:

Sealing leaks helps to prevent outdoor pollutants, allergens, and moisture from entering your home, which can improve your indoor air quality and reduce the risk of mold growth.

System Longevity:

Reducing the strain on your HVAC system by minimizing air leaks can extend the life of your heating and cooling equipment, saving you money on repairs and replacements.

Stay Connected

Follow us on Social Media

Ready to Get Started?

Call us or fill out our contact form to get a free quote.

Copyright 2026. No-Draft. All Rights Reserved.

Design by Invision Web design.